User’s Guide

Configuration

There are three methods to configurate the cases.

1. Using Existing Cases

You can use the provided config.xml and connection.xml files in the Cases/ directory.

We provide four example in Cases folder:

Residential Case study(

ResidentialCase)Multienergy system case study(

MultienergyCase)Electricity market game case study (

GameCase) For more information about the electricity market case study, you can reference the Msc thesis, andDistribution voltage control case study (

DNcontrolCase) .

The config.xml file is used to define the models in the case and where to

run the model.

For example in the config.xml below, we built a simulation with only Wind and PV models.

In the configuration below, the wind model runs (localy? in the master?) and the PV model runs in a client with IP ‘192.168.0.1’, and the master get the PV model’s information from the port the client’s port 5123.

#'Wind' ,'python','Models.Wind.wind_mosaik:WindSim'

#'PV','connect', '192.168.0.1:5123'

<?xml version='1.0' encoding='utf-8'?>

<data>

<row>

<index>0</index>

<model>Wind</model>

<method>python</method>

<location>Models.Wind.wind_mosaik:WindSim</location>

</row>

<row>

<index>1</index>

<model>PV</model>

<method>connect</method>

<location>192.168.0.1:5123</location>

</row>

The connection.xml file sets how the message are transfered from one model to others.

For example in the snippet below, the ctrl model sends information about ‘flow2e’ to electrolyser to control its hydrogen generating speed.

The electrolyser send the ‘h2_gen’ information to model h2storage ‘h2_in’ to control the hydrogen storing speed.

#['ctrl', 'electrolyser', 'flow2e'],

#['electrolyser', 'h2storage', 'h2_gen', 'h2_in'],

<row>

<index>13</index>

<send>ctrl</send>

<receive>electrolyser</receive>

<message>flow2e</message>

<more/>

</row>

<row>

<index>14</index>

<send>electrolyser</send>

<receive>h2storage</receive>

<message>h2_gen</message>

<more>h2_in</more>

2. Using the ‘build configuration’ Script

User can configure a case using the python scripts build_configuration_xml in the folder configuration/ directory. By executing the script, the config.xml and connection.xml

file will be automatically built. Use change the configuration by changing the parameters sim_config and connection.

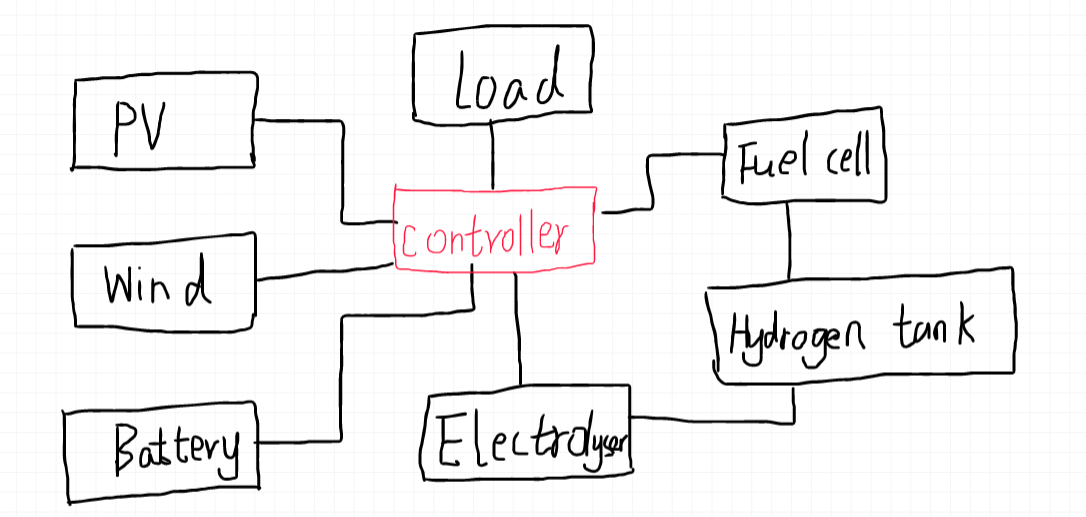

3. Drawing Configurations

The Illuminator also provide visualized method to create configuration. The user can use a smart board, touch screen or mouse to configurate

the case. To to this, firstly, run drawpptx.py.

Secondly, draw a configuration by hand and save as a PowerPoint file with a .pptx file extension. For example:

Thirdly, run the script readppt_connectionxml.py to build the configuration files.

Defining Models

Model parameters, results presentation and real-time simulation are all set in the file buildmodelse.py.

Battery_initialset = {'initial_soc': 20}

Battery_set = {'max_p': 500, 'min_p': -500, 'max_energy': 500,

'charge_efficiency': 0.9, 'discharge_efficiency': 0.9,

'soc_min': 10, 'soc_max': 90, 'flag': 0, 'resolution': 15} #p in kW

#Set flag as 1 to show fully discharged state; -1 show fully charged,0 show ready to charge and discharge

h2storage_initial = {'initial_soc': 50}

ttrailers_initial = {'initial_soc': 20}

h2_set = {'h2storage_soc_min': 10, 'h2storage_soc_max': 90, 'max_h2': 0.3,

'min_h2': -0.3, 'flag': 0, 'capacity':30, 'eff': 0.94, 'resolution':resolution}

h2trailer_set = {'h2storage_soc_min': 10, 'h2storage_soc_max': 90, 'max_h2': 0.3,

'min_h2': -0.3, 'flag': 0, 'capacity':3000, 'eff': 0.94, 'resolution':resolution}

# max_h2 min_h2 in m^3/min;

# flag as 1 to show fully discharged state; -1 show fully charged,0 show ready to charge and discharge

# approx efficiency of compressed hydrogen storage tanks. Roundtrip efficiency

# Capacity is max m3 of hydrogen that it can contain

pv_panel_set ={'Module_area': 1.26, 'NOCT': 44, 'Module_Efficiency': 0.198, 'Irradiance_at_NOCT': 800,

'Power_output_at_STC': 250,'peak_power':600}

pv_set={'m_tilt':14,'m_az':180,'cap':500,'output_type':'power'}

# 'NOCT':degree celsius; 'Irradiance_at_NOCT':W/m2 This is the irradiance that falls on the panel under NOCT conditions

# KW. Available in spec sheet of a module

load_set={'houses':1000, 'output_type':'power'}

Wind_set={'p_rated':300, 'u_rated':10.3, 'u_cutin':2.8, 'u_cutout':25, 'cp':0.40, 'diameter':22, 'output_type':'power'}

Wind_on_set={'p_rated':300, 'u_rated':10.3, 'u_cutin':2.8, 'u_cutout':25, 'cp':0.40, 'diameter':22, 'output_type':'power'}

Wind_off_set={'p_rated':200, 'u_rated':7.5, 'u_cutin':2.8, 'u_cutout':15, 'cp':0.40, 'diameter':15, 'output_type':'power'}

# p_rated # kW power it generates at rated wind speed and above

# u_rated # m/s #windspeed it generates most power at

# u_cutin # m/s #below this wind speed no power generation

# u_cutout # m/s #above this wind speed no power generation. Blades are pitched

# cp # coefficient of performance of a turbine. Usually around0.40. Never more than 0.59

# powerout = 0 # output power at wind speed u

fuelcell_set={'eff':0.45, 'term_eff': 0.2,'max_flow':100, 'min_flow':0,'resolution':resolution}

electrolyser_set={'eff':0.60,'resolution':resolution, 'term_eff': 0.2,'rated_power':2.3,'ramp_rate':1.5}

# term_eff: percentage of power transformed in effective heat

RESULTS_SHOW_TYPE={'write2csv':True, 'dashboard_show':False, 'Finalresults_show':True,'database':False,'mqtt':False}

#'write2csv':True/Flause Write the results to csv file

# #'Realtime_show':True/Flause, show the results in dashboard

# 'Finalresults_show':True/Flause, show the results after finish the simulation

# 'mqtt'::True/Flause, send the results outside through mqtt protocol. When this is True, you must set the receiver correctly.

enetwork_set={'max_congestion': 1000, 'p_loss_m': 0.56, 'length': 300}

h2network_set={'max_congestion': 700, 'V': 0.0314, 'leakage': 0.03, 'ro': 0.0899}

# max_congestion: max internal pressure bar

# leakage: % of internal flow loss

# ro: gas density kg/m^2 at STP

heatnetwork_set = {'max_temperature': 300 + 275.15, 'insulation': 0.02, 'ext_temp': 25 + 275.15, 'therm_cond': 0.05,

'length': 100, 'diameter': 0.3, 'density': 1000, 'c': 4.18}

# max_temperature : max_temperature allowed before congestion # K

# insulation: insulation layer diameter #m

# ext_temp: external temperature # K

# therm_cond: thermal conductivity # W/(m·K)

# leght: lenght of pipeline # m

# diameter: pipe diameter # m

# density: water density # kg/m^3

# c : Thermal capacity of the medium #kJ/(kg·K)

h2demand_r_set={'houses':0.5}

h2demand_fs_set={'tanks':1}

h2demand_ev_set={'cars':1}

h2product_set={'houses':1}

heatstorage_set = {'soc_init': 20, 'max_temperature': 300 + 275.15, 'min_temperature': 25+275.15, 'insulation': 0.20,

'ext_temp': 25 + 275.15, 'therm_cond': 0.03,

'length': 2.5, 'diameter': 1.5, 'density': 1000, 'c': 4.18, 'eff': 0.85, 'max_q': 300, 'min_q': -300}

# max_temperature : max_temperature allowed before soc max # K

# min_temperature : max_temperature allowed before soc min # K

# insulation: insulation layer diameter #m

# ext_temp: external temperature # K

# therm_cond: thermal conductivity # W/(m·K)

# leght: lenght of pipeline # m

# diameter: pipe diameter # m

# density: water density # kg/m^3

# c: Thermal capacity of the medium #kJ/(kg·K)

# eff: charge/discharge efficiency

# Seasonal storage

heatstorage_s_set = {'soc_init': 80, 'max_temperature': 300 + 275.15, 'min_temperature': 25+275.15, 'insulation': 0.20,

'ext_temp': 25 + 275.15, 'therm_cond': 0.03,

'length': 10, 'diameter': 2, 'density': 1000, 'c': 4.18, 'eff': 0.85, 'max_q': 300, 'min_q': -300}

# Daily storage

heatstorage_d_set = {'soc_init': 80, 'max_temperature': 300 + 275.15, 'min_temperature': 25+275.15, 'insulation': 0.20,

'ext_temp': 25 + 275.15, 'therm_cond': 0.03,

'length': 0.5, 'diameter': 1, 'density': 1000, 'c': 4.18, 'eff': 0.85, 'max_q': 300, 'min_q': -300}

heatdemand_i_set={'factories':1}

heatdemand_r_set={'houses':1}

heatproduct_set={'utilities':1}

hp_params = {'hp_model': 'Air_8kW',

'heat_source': 'air',

'cons_T': 35,

'heat_source_T': 4,

'T_amb': 25,

'calc_mode': 'fast',

'number': 15}

eboiler_set = { 'capacity':30, 'min_load':5, 'max_load':10, 'standby_loss':0.2,

'efficiency':0.8,'resolution':resolution}

realtimefactor=0

#0 as soon as possible. 1/60 using 1 second simulate 1 mintes

metrics = {'prosumer_s1_0': {'MC': [0.07, 0.10], 'MB': [0.12],'MO': [0.05, 0.25], 'MR': [0.40]},

'prosumer_s1_1': {'MC': [0.27], 'MB': [0.20], 'MO': [0], 'MR': [0.33]},

'prosumer_s1_2': {'MC': [0.33, 0.07], 'MB': [0.18], 'MO': [0.09, 0.22], 'MR': [0.15]},

'prosumer_s1_3': {'MC': [0], 'MB': [0.50], 'MO': [0], 'MR': [0.50]},

'prosumer_s1_4': {'MC': [0.10,0.37], 'MB': [0.44], 'MO': [0.01, 0.20], 'MR': [0.20]},

'prosumer_s1_5': {'MC': [0.12], 'MB': [0.28], 'MO': [0.17], 'MR': [0.19]},

}

Running Simulations

This was set up as a shortcut to collect data and do plotting

Run the simulation creator_**.py to create and run the simulation based on the provided case and scenario.

To see the results via the dashboard, you need Internet and sign up in wandb software.

The simple_test.py shows a simple case with the configuration inside of the file.

Demos

Four case studies show how to use Illuminator, and to verify the Illuminator’s performance.

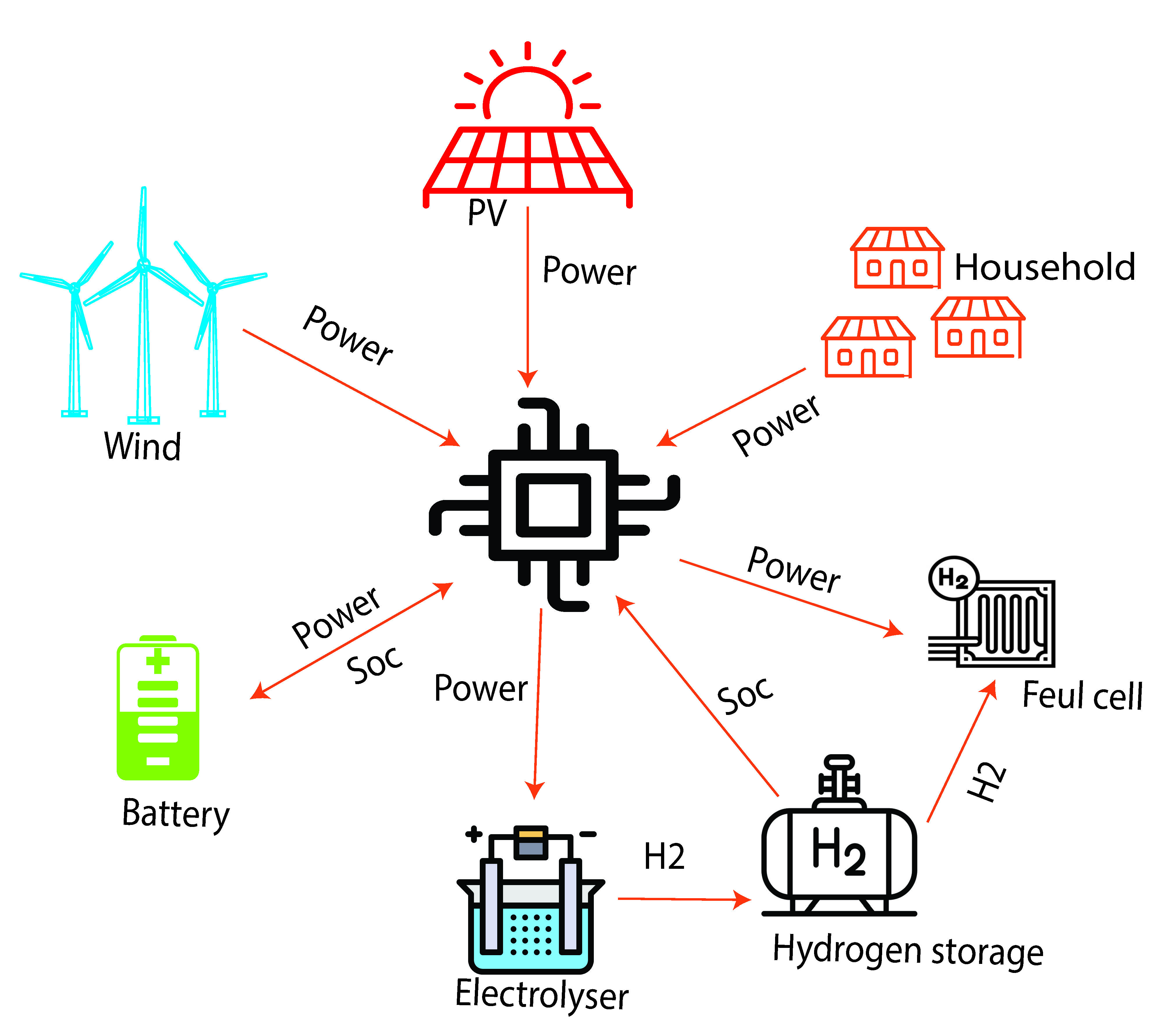

1. Residencial Case

The first demo shows a residential energy community system which include Households,

PV panels, Wind generators, Battery and Hydrogen system

to achieve electric power self-sufficiency.

The controller’s algorithm in this case runs in the master RasPi Controllers/ResidentialController, and

the rest client simulators are separately deployed in different

RasPis. The data flow between the simulators (clients) is also shown in

the figure below. Based on the inputs, including the generated power

from PV and Wind, the consuming power of households, and

the state of charge (Soc) of the Battery and Hydrogen, the

controller decides the power from the Battery and Fuel cell

and the power to the Electrolyser.

In the case study, we use

simple logic to achieve self-sufficiency. If Battery has enough

capacity for charging or discharging to achieve power balance,

use the Battery first. If Battery doesn’t have enough capacity

to achieve power balance, then use Electrolyser or Fuel cell

to achieve power balance. All the input data are in the Scenarios/ directory and all the output data are in file Result/ResidentialCase/.

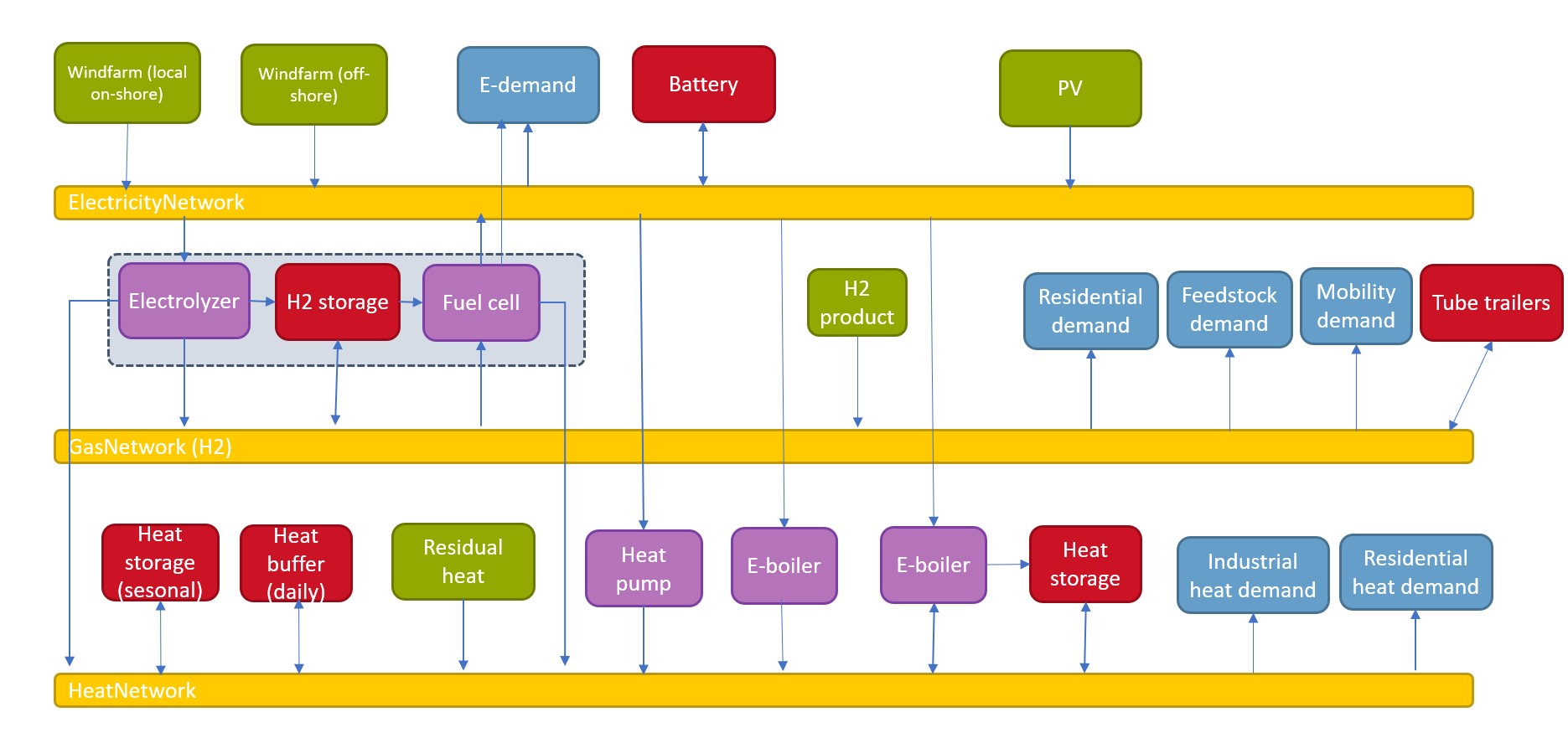

2. Multi-carriers Case

The second demo shows the Multi-carriers energy system, which incorporate the electricity network, hydrogen network and heat network. All the energy assets are shown in the below figure.

3. Electricity Trade Game

The third demo shows the electricity trade game and more details please refer to this Msc thesis

4. CIGRE LV Case

The fourth demo shows the voltage control in the CIGRE LV voltage network. The network model is in the Models/EleDisNetworkSim/ directory, and the control method is in Controllers/NetVoltageControllerSim/